Technical

Cleanliness Inspection Solution

Why need Technical Cleanliness Inspection:

As we all know, the cleanliness of component' surfaces will affect the reliability and durability of advanced technology products in automobile, airplane and medical industry. Chip, burr, casting sand, welding slag, abrasive and other solid particles will cause the following damages: bearing blockage, valve blockage, nozzle blockage, short circuit, cylinder leakage, pump burning, etc.

Jetblue CleanTec provides you with a complete set of instruments and equipment for technical cleanliness testing independently developed and produced according to ISO16232, VDA19.1, ISO4406 and other internal specifications or standards, including membranes, tweezers, petri dishes, etc. required for testing, that is, particles are separated (extracted) from components, and a suitable optical evaluation system is used for final analysis. At the same time, according to your requirements, we can build a well-equipped cleanliness testing laboratory for you, and its clean room grade meets the ISO 8 standard.

Application standards:

|

Standards |

Mainly used for |

|

ISO 11218:1993 |

Aerospace - Cleanliness classification for hydraulic fluids |

|

ISO 12345:2013 |

Diesel engines - Cleanliness assessment of fuel injection equipment |

|

ISO 14952:2003 |

Space systems - Surface cleanliness of fluid systems |

|

ISO 16232-10:2007 |

Road vehicles - Cleanliness of components of fluid circuits |

|

ISO 4406:1999 |

Hydraulic fluid power - Fluids - Method for coding the level of contamination by solid particles |

|

ISO 4407:1991 |

Hydraulic fluid power - Fluid contamination - Determination of particulate contamination by the counting method using a microscope |

|

NAS 1638:2011 |

Cleanliness requirements of parts used in hydraulic systems |

|

NF E 48-651:1986 |

TRANSMISSIONS HYDRAULIQUES - FLUIDES - DETERMINATION DE LA POLLUTION PARTICULAIRE PAR LA METHODE DE COMPTAGE AU MICROSCOPE |

|

NF E 48-655:1989 |

Hydraulic fluid power - Fluids - Particulate contamination - Expression of results |

|

NF ISO 21018-1:2008 |

Hydraulic fluid power - Monitoring the level of particulate contamination of the fluid |

|

SAE AS 4059:2011 |

Aerospace Fluid Power - Cleanliness Classification for Hydraulic Fluids |

|

VDA 19.1:2015 |

Fluid circuits in automotive-Inspection of Technical Cleanliness |

Detection process:

|

Step 1 |

Step 2 |

Step 3 |

Step 4 |

Step 5 |

Step 6 |

|

EXTRACTION |

FILTRATION |

WEIGHING |

INSPECTION |

REVIEW |

RESULTS |

|

1.Extract the particles from the part or component by use of fluid |

2. Filter the fluid through a filter membrane to gather the residual dirt of washed components. |

|

|

|

|

3.Take out the filter membrane with the extracted particles, dry or weight |

4.Put the filter membrane on the technical cleanliness inspection system to scan |

|

|

|

|

5.Inspection and review the particles by our software. |

6. The report will show you the sizes and numbers of particles or fibers according to VDA19.1, ISO16232, ISO4406 and internal specifications. |

|

|

|

Equipment composition:

|

No. |

Product Picture |

Item |

Function |

|

1 |

|

Component Cleanliness Cabinet |

Particle extraction is carried out on the surface of parts by liquid high-pressure washing or ultrasonic wave. |

|

2 |

|

Electric blast drying oven |

The filter membrane is dried before and after filtration. |

|

3 |

|

BSM-1.204 1/10000 Balance |

Used for weighing the filter membrane before and after filtration (the quality of impurities can be obtained). |

|

4 |

|

Technical Cleanliness Inspection System |

Scanning and analyzing the particulate matter on the filter membrane, the results will show you the sizes and numbers of reflecting particles, reflecting particles fibers, regular particles, regular fibers according to VDA19.1, ISO16232, ISO4406 and internal specifications. |

|

5 |

|

Cleaning Agent Petri dish Tweezers Dust-free clothing Drying dish |

Auxiliary equipment |

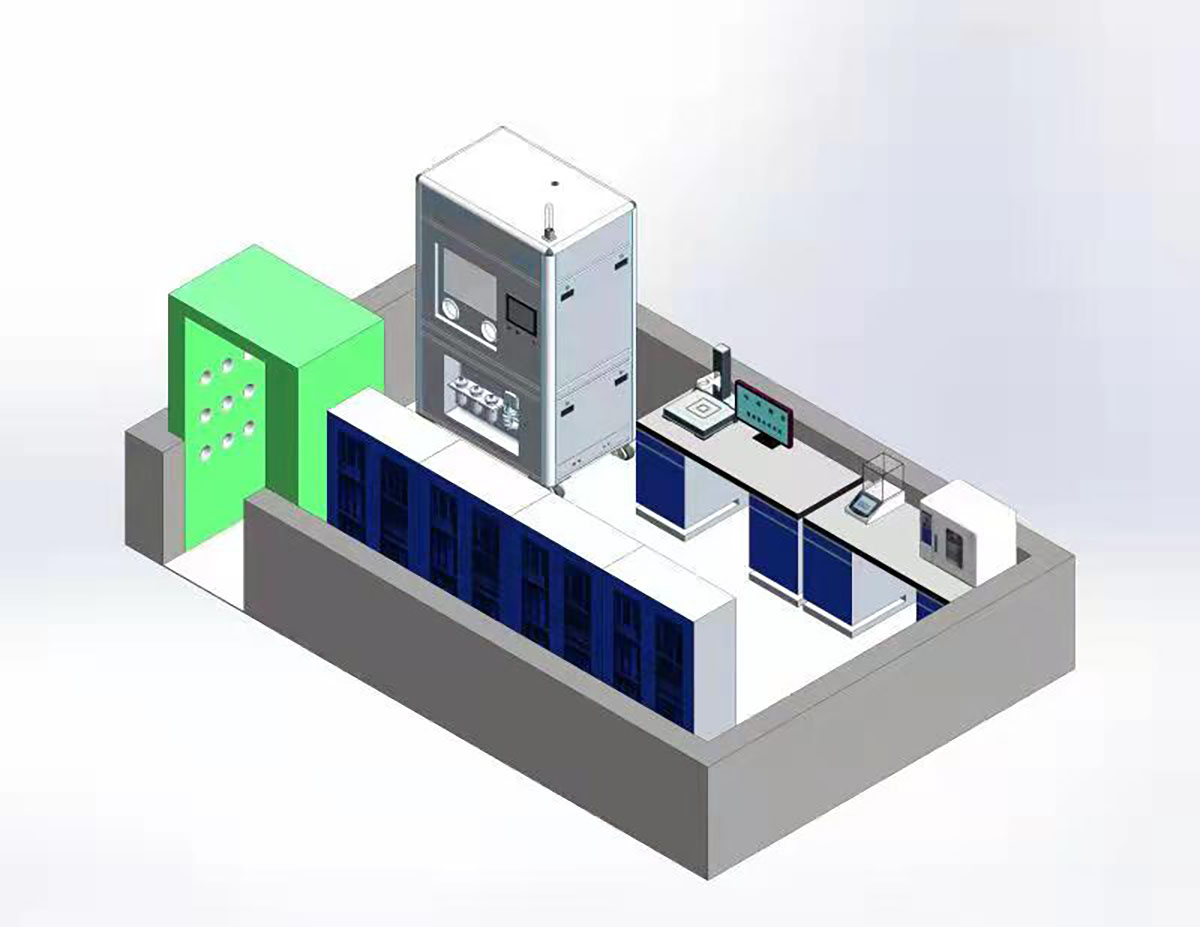

Laboratory plan: